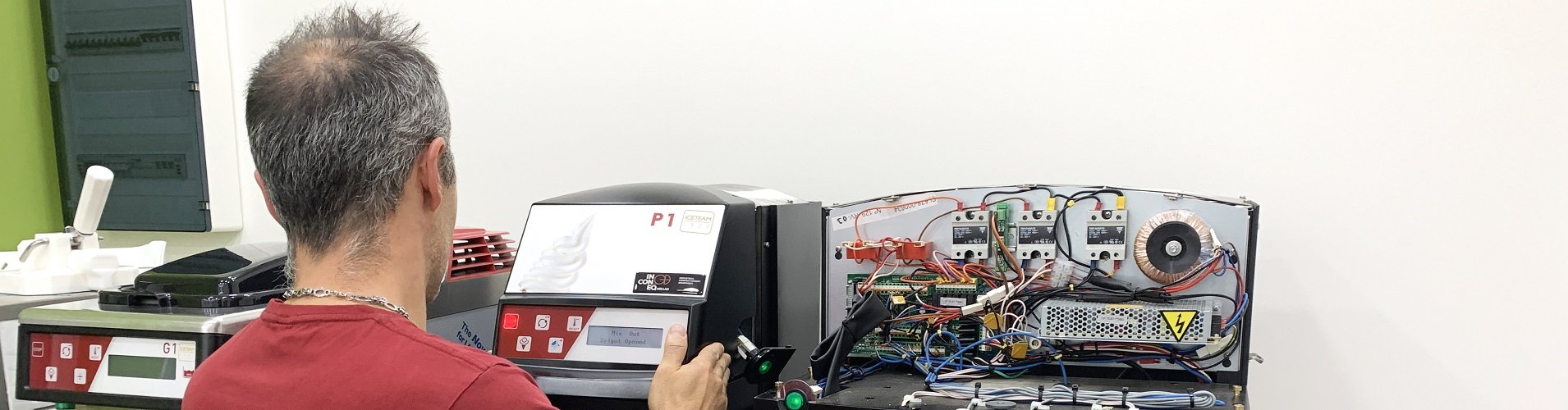

Counter-Top Batch Freezer Iceteam1927 Coldelite Model Compacta 4

Counter-Top Batch Freezer Iceteam1927 Coldelite Model Compacta 4

In one machine the wholw cycle of Gelato production

is an all-in-one counter top machine that allows you to produce high quality Italian Gelato

Horizontal mixer

The ingredients are poured into the hopper of the top cylinder and finely mixed.High rotation speed allows the complete dispersion of dry ingredients in the mix.

Pasteurization

Pressing the heating button will start the cycle, which can be regulated to up to 95ºC.An acoustic/visual signal shows that the temperature has been reached.

Direct transfer

The prepared mix is transferred to the freezing cylinder through an outer spigot that can be removed and washed easily for the maximum hygiene.

Batch freezer

Pressing the button with the cone will start the gelato production cycle.An acoustic/visual signal shows that the gelato is ready.

Gelato extraction

Extraction is complete and fast due to the high rotation speed of the paddles and the opening for the gelato.

Compacta 4

The Compacta 4 system always makes gelato with perfect consistency, both for rich and delicate mixes.

Chimney system

Cooling system with exit from the top, to save space in the top.

LIMIDED SPACE LIMITED INVESTMENT LOW OPERATIONAL COST

CONTINUOUS PRODUCTION

Since the two cylinders can work at the same time, while the first batch of Gelato is in the batch freezer, the second one can be pasteurised above, this means that you can make all the gelato you want, in sequence.

Compacta 4

- Compacta 4 features a two-in-one structure

- in the upper part the horizontal cylinder mixes ingredients

- in the lower part the second horizontal cylinder makes gelato.Therefore it is a all-in-one equipment, resuming the whole production process of hand made gelato

- the Mixer, to mix together the raw ingredients

- the Pasteurizer, to achievetop hygiene of the mix

- the Freezer to produce gelato "sorbetto" and fruit creams

- Advanages: Customised batch freezing cycles

- Reduced power consumption

- Reduced water consumption

- Silent operation

- Reduced environmental impact

- Reduced minimum production amounts

- Smooth operation

- Increaced duration for mechenical parts

-20210317-143128-w1024-h768-100.jpg)